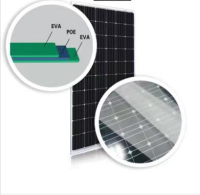

Anti PID (SV-15296P & SV-15297P)

Changzhou Sveck Photovoltaic New Materials Co, Ltd.| タイプ: | 超高速キュア |

|---|---|

| 地域: |

中国

|

注意:お問い合わせはChangzhou Sveck Photovoltaic New Materials Co, Ltd..に直接に送信されます。

代替製品

EVA-S201MT&S201MR

HIUV New Materials

スタート価格

¥157 / m2

- 厚さ: 0.5-0.7 mm

- タイプ: 高速キュア

- 幅: ≤1100 mm

- ロールの長さ: 100-150 m

- VA含有量: 26.5-30.5 %

製品の特徴

| 製品の特徴 | |

|---|---|

| タイプ | 超高速キュア |

| 厚さ | 0.45-0.9 mm |

| ロールの長さ | 100 m |

| 密度 | 0.96 g/cm3 |

| ゲル含有量 | ≥75 % |

| 安定特性 | |

| 引張強度 | 16 Mpa |

| 伸長率 | 550 % |

| 剥離強度(保護剤 - ガラス) | ≥60 N/cm |

| 剥離強度(保護剤 - バックシート) | ≥40 N/cm |

| 熱収縮率(幅/ TD) | ≤3 % |

| 熱収縮率(幅/ TD) | ≤2 % |

| 体積抵抗率 | >1x10 ^14 Ω·cm |

| 紫外線老化(黄·インデックス) | ≤2 △YI |

| 光及び熱特性 | |

| 光線透過率 | ≥80 % |

関連製品

-

White EVA fil...

Sveck Photovolt... 超高速キュア -

¥191 / Wp

¥191 / WpEVA Film - Ul...

Dr. HWC 超高速キュア -

White II EVA ...

Sveck Photovolt... 超高速キュア -

¥208 / Wp

¥208 / WpEVA film tran...

Feiyu EVA 超高速キュア -

PO film (SE-5...

Sveck Photovolt... 高速キュア -

Sinopont EVA ...

Sinopont Techno... 標準キュア -

PO II FLIM (C...

Sveck Photovolt... 超高速キュア -

POE

Sinopont Techno... 標準キュア